The uptime of a pumpjack greatly affects the oil production. As operators of oil fields, it is important to know the run status of all pumpjacks to ensure that exceptions can be found in time, maximizing the uptime of the pump jacks, optimizing operations, and increasing the productivity of the oil field.

REMOTE PUMPJACKS MONITORING SOLUTION

INDUSTRY SOLUTIONS

The uptime of a pumpjack greatly affects the oil production. As operators of oil fields, it is important to know the run status of all pumpjacks to ensure that exceptions can be found in time, maximizing the uptime of the pump jacks, optimizing operations, and increasing the productivity of the oil field.

REMOTE PUMPJACKS MONITORING SOLUTION

INDUSTRY SOLUTIONS

The uptime of a pumpjack greatly affects the oil production. As operators of oil fields, it is important to know the run status of all pumpjacks to ensure that exceptions can be found in time, maximizing the uptime of the pump jacks, optimizing operations, and increasing the productivity of the oil field.

CHALLENGES

Run Status Unknown

It is difficult to know in time which pump jacks in the distant oil fields have been idling or stopped and to get the exact data requires visits to the site and time for visual inspection. Thus, production is severely affected and the cost is high.

Difficult to

Get Critical Data

Get Critical Data

It is time-consuming to manually record the current run statuses of pumping units and to screen out the most useful data. Moreover, the data may be inaccurate.

Delayed/Unreliable

Data Transmission

Data Transmission

Operating data of oil pumpjacks may fail to be reported by a wired digital monitoring system due to a circuit or power failure.

YES

CHALLENGES

Run Status Unknown

It is difficult to know in time which pump jacks in the distant oil fields have been idling or stopped and to get the exact data requires visits to the site and time for visual inspection. Thus, production is severely affected and the cost is high.

Difficult to

Get Critical Data

Get Critical Data

It is time-consuming to manually record the current run statuses of pumping units and to screen out the most useful data. Moreover, the data may be inaccurate.

Delayed/Unreliable

Data Transmission

Data Transmission

Operating data of oil pumpjacks may fail to be reported by a wired digital monitoring system due to a circuit or power failure.

YES

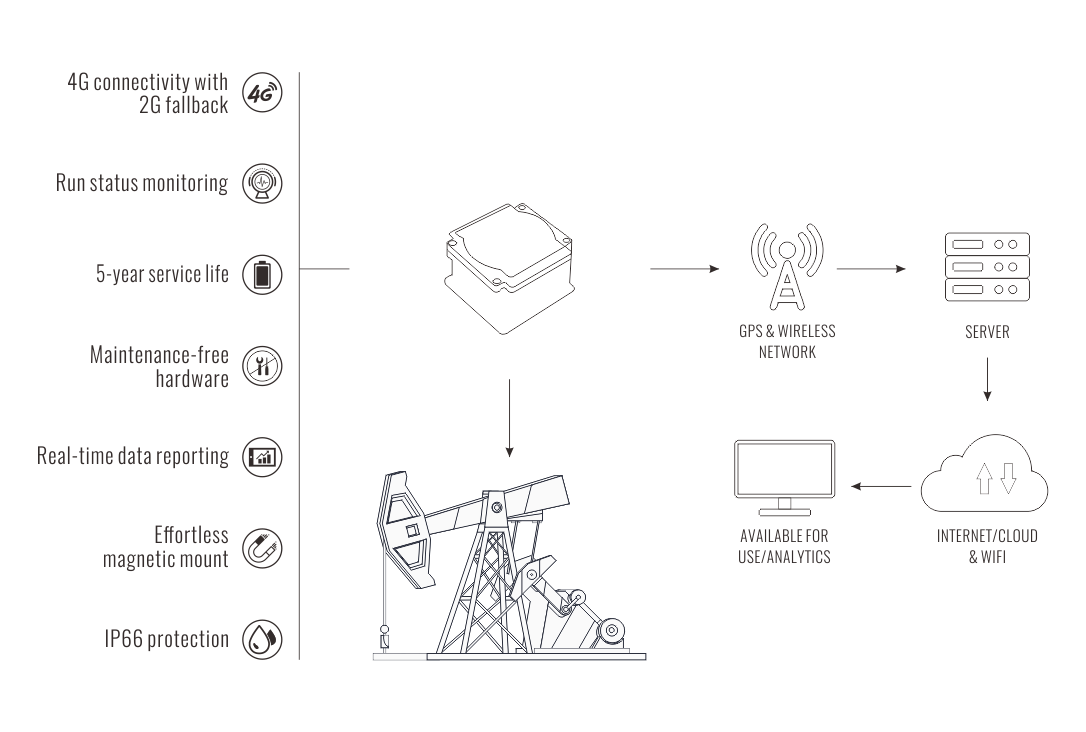

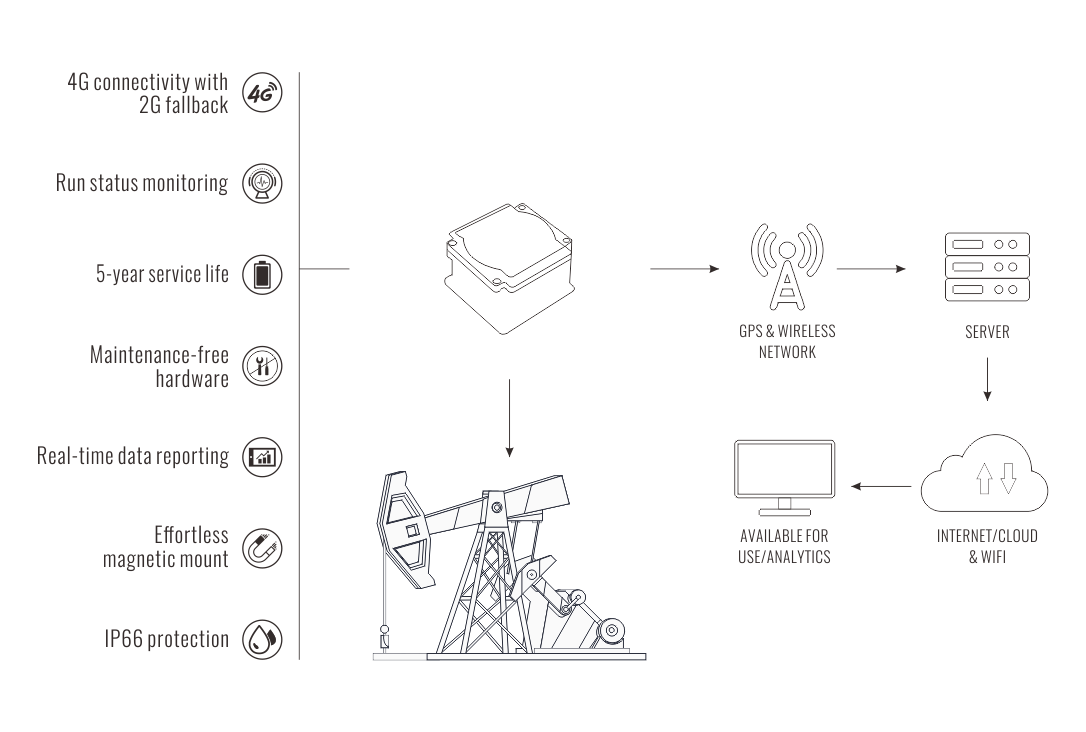

SOLUTION

DEVICE Run time efficiency monitoring devices installed on the walking beams collect the run status data (start, stop, swing) of the pumpjacks in real-time and upload the data using the cellular network to the cloud server.

CLOUD The cloud server analyzes the data and visualizes them in intuitive graphs and lists on the designated web client or mobile app.

PLATFORM The platform alerts operators if any exception including unexpected stops or low battery occurs to enable operators to act accordingly.

SOLUTION

DEVICE Run time efficiency monitoring devices installed on the walking beams collect the run status data (start, stop, swing) of the pumpjacks in real-time and upload the data using the cellular network to the cloud server.

CLOUD The cloud server analyzes the data and visualizes them in intuitive graphs and lists on the designated web client or mobile app.

PLATFORM The platform alerts operators if any exception including unexpected stops or low battery occurs to enable operators to act accordingly.

BENEFITS

Maximize uptime and oil production and optimize operations with real-time status feedback.

Higher Production

Save manpower from frequent visits to and fro oil fields.

Labor-Saving

Save money on cables and cabling with the magnetic mount design.

Budget-Friendly

Reduce the time to scramble critical data from heaps of paper documents with intuitive graphs and lists.

Visible Data

Guarantee uninterrupted data transmission with the internal battery featuring 5+ years of service life.

Reliable Transmission

Ensure reliable operation in various harsh environments with a wide operating temperature range (–40℃ to +85℃) and the IP66 protection and guarantee production efficiency.

Waterproof Design

Previous

Next

BENEFITS

Maximize uptime and oil production and optimize operations with real-time status feedback.

Higher Production

Save manpower from frequent visits to and fro oil fields.

Labor-Saving

Save money on cables and cabling with the magnetic mount design.

Budget-Friendly

Reduce the time to scramble critical data from heaps of paper documents with intuitive graphs and lists.

Visible Data

Guarantee uninterrupted data transmission with the internal battery featuring 5+ years of service life.

Reliable Transmission

Ensure reliable operation in various harsh environments with a wide operating temperature range (–40℃ to +85℃) and the IP66 protection and guarantee production efficiency.

Waterproof Design

HARDWARE

HARDWARE

The uptime of a pumpjack greatly affects the oil production. As operators of oil fields, it is important to know the run status of all pumpjacks to ensure that exceptions can be found in time, maximizing the uptime of the pump jacks, optimizing operations, and increasing the productivity of the oil field.

REACH OUT TO DISCOVER

HOW SOLUTION CAN IMPROVE YOUR BUSINESS

HOW SOLUTION CAN IMPROVE YOUR BUSINESS

REACH OUT TO DISCOVER

HOW SOLUTION CAN IMPROVE YOUR BUSINESS

HOW SOLUTION CAN IMPROVE YOUR BUSINESS

PLATFORM

EN

EN ES

ES PT

PT TH

TH VN

VN JP

JP